Welcome to Plasma Processes

We are a leader in high-performing material solutions for products in extreme environments. We utilize unique material processes to make your technologies go faster, further, and for longer.

WHO WE ARE

Our Capabilities

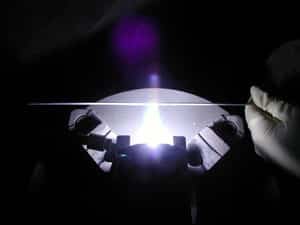

Coating Processes

Plasma has a unique ability to provide the best plasma coating solution for our customers’ needs based on performance, cost, and schedule requirements.

Plasma is an additive manufacturing (AM) expert and has been producing components with additive techniques for decades.

Plasma Processes was founded as a materials science and research company, uniquely positioned to solve our customers’ most complex challenges.

WHO WE ARE

Plasma Processes

For 30+ years we have provided unique material solutions for products that are introduced to extreme environments and conditions. We utilize a variety of processes to provide engineering, manufacturing, and testing services to our customers.

ABOUT OUR COMPANY

Plasma Processes, LLC was founded in 1993 and is an AS9100D/ISO9001 certified non-traditional defense contractor. We specialize in the development, manufacture, and coating of engineered materials and their applications for extreme conditions. We offer a wide range of manufacturing and coating processes, each with unique characteristics for specific applications.

Explore Our Facility

Plasma has both of its buildings and facilities located within Huntsville, Alabama and has > 80,000 ft of manufacturing and office space. Its facilities house equipment to support high-end manufacturing, testing, and assembly.

Extensive Capabilities

Plasma has a heritage of performing high-temperature coatings for 30+ years. However, we do much more than just high-temperature coatings. We are vertically integrated and perform end-to-end processing for our customers such as design/development, testing/trades, machining, surface preparation, coatings, post processing, assembly, quality, and any other supply chain needs. Internally, we have the capability to perform various processes including Cold Spray, Atmospheric Plasma Spray (APS) or Inert Plasma Spray, Vacuum Plasma Spray (VPS), Shrouded Plasma Spray, and more. This allows us to perform coatings for things like thermal protection systems (TPS) or thermal barrier coatings (TBC), radiation shielding, rain penetration, environmental barrier coatings (EBC), specialty coatings like stealth, and more. We also provide additive manufacturing, machining, grit blasting, testing, and more for our customers.

The Highest Quality

Our quality team is highly trained and advanced in both equipment and processes. We are certified to AS9100D with ISO 9001:2015 Standard along with many customer specific specifications and certifications. We have experience performing to government, commercial, DOD and scientific, R&D vs. production, and more types of quality requirements across our 30+ years of heritage

WHO WE ARE

Products Overview

Coatings/Shielding

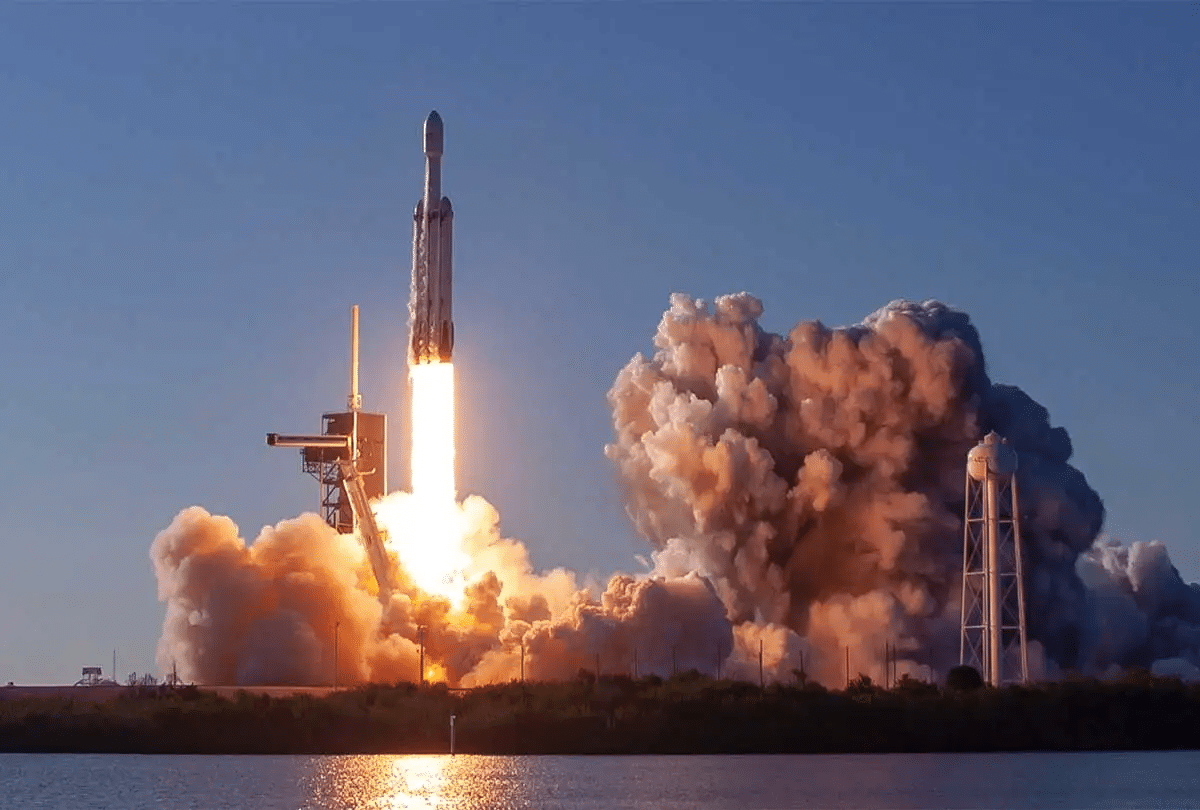

Plasma has been applying our own or customer preferred Thermal Barrier Coatings (TBC/TPS), Environmental Barrier Coatings (EBC), Radiation, Ablative, Abrasion, Corrosion, Anti-Erosion, and other specialty coatings for 30+ years. We use our coatings to help our customers products go faster, further, and for longer under extreme conditions.

Plasma has been building a variety of propulsion components through additive manufacturing capabilities such as El-Form, Plasma Spray, 3D printing, and even regular machining. We provide commercial and other types of components that can be used in solid rocket motors (SRM), divert and attitude control (DAC), rotating detonating engines (RDE), ramjet, scramjet, and other types of propulsion systems.

Rubicon Propulsion Products

Plasma has produced, delivered, and flown hundreds of thrusters in space. We use our advanced El-Form technology to manufacture industry leading thrusters.

Materials and Testing

We provide the following tests and services:

- Spherical Particle Shapes

- High Density

- Improved Flow

- Low Oxygen Content

- Controlled Particle Size Distribution

- Alloying

- Custom Powder Formulation

- Full Metallurgy Lab

- Arc-Jet and HVOF Testing

We can help develop and perform risk reduction on material selection for programs.

Markets We Serve

Plasma Processes offers innovative products and services for demanding markets and is dedicated to providing customers with advanced materials solutions that enable high performing products. We provide engineered products and coatings for customers’ markets that need unique requirements to succeed in high-stress environments.

Our Customers

newsroom

Lastest Articles

- News

- News

SAN FRANCISCO – Rubicon Space Systems won a NASA contract to develop a 110-newton

- News

Plasma Processes’ green propellant technology was showcased in the Missile Defense Agency’s Tech Update,