Quality

Our mission is to meet or exceed our customers’ expectations for quality. We believe excellence in quality starts with a commitment to fully understand our customers’ requirements and needs. Our quality management system is currently certified to the AS9100D with ISO 9001:2015 standard.

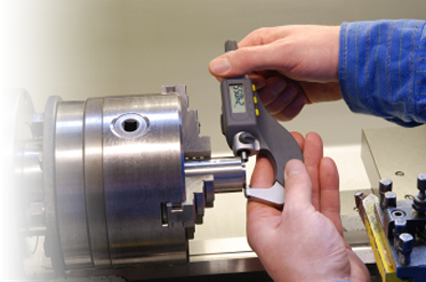

Plasma Processess’ quality assurance team has significant experience and consistently gets top marks on customer scorecards. Inspection equipment is calibrated and traceable to NIST. Give us a call or schedule a visit to learn more.

AS9100 Certified

Inspection and Analysis

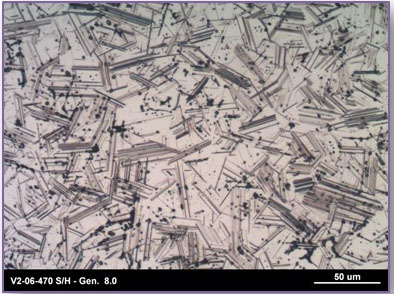

Metallographic Analysis